|

Physical Properties |

Value |

Unit |

Test Method |

|

Hardness (5 sec) |

91 |

Shore A |

ASTM D2240 |

|

Specific Gravity |

1.16 |

|

ASTM D792 |

|

Tensile Strength |

6750 (47) |

psi (MPa) |

ASTM D412 |

|

Ultimate Elongation |

400 |

% |

“ |

|

Tensile Stress at |

|

|

|

|

- 100 % Elongation |

1500 (10) |

psi (MPa) |

ASTM D412 |

|

- 300 % Elongation |

4200 (29) |

psi (MPa) |

“ |

|

Tear Strength |

|

|

|

|

Graves |

583 (10.2) |

lb/in (kg/mm) |

ASTM D624 (die C) |

|

Trouser |

144 (2.5) |

lb/in (kg/mm) |

ASTM D470 |

|

Taber Loss (1000 rev) |

0.0019 (54) |

oz (mg) |

ASTM D3389 (H18, 1000g) |

|

Tm (by DSC) |

342 (172) |

°F (°C) |

C & J Advanced Materials |

|

Tg (by DSC) |

-36 (-38) |

°F (°C) |

C & J Advanced Materials |

|

|

°F/°C |

|

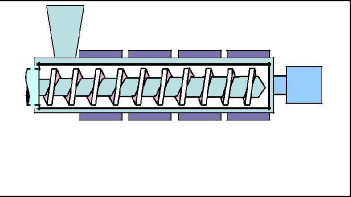

Zone 1 |

355/180 |

|

Zone 2 |

365/185 |

|

Zone 3 |

375/190 |

|

Zone 4 |

385/195 |

|

Adapter (5) |

395/195 |

|

Die Zone 1 |

400/205 |

|

Die Zone 2 |

400/205 |

|

Application Properties |

Value |

Unit |

Test Method |

|

UL 94 Vertical Flame Test, 30 mils (0.76 mm) |

V-2 |

N/A |

ASTM D3801 |

|

RT Burst Pressure |

630 (4.3) |

psi (MPa) |

ISO 7628/1 |