Type : Noveon® ZHF78AT3 is aromatic polyether-based NHFR thermoplastic polyurethane. Appearance : Transparent cylindrical pellets.

Application : Cable and tube Extrusion

|

MECHNICAL PROPERTIES |

TEST METHOD |

UNIT |

VALUE* |

|

Hardness (3s) Specific Gravity |

ISO 868 ISO 2781 |

SHORE A g/cm3 |

78A 1.13 |

|

Tensile Strength |

ISO 37 |

MPa |

32 |

|

Ultimate Elongation |

|

% |

730 |

|

Tensile stress at |

S1 type dumbbells |

|

|

|

- 50% Elongation |

Speed=500mm/min |

MPa |

3.6 |

|

- 100% Elongation |

|

MPa |

4.4 |

|

- 300% Elongation |

|

MPa |

7.3 |

|

Tear Resistance |

ISO 34 |

kN/m |

135 |

|

Flammability |

UL-94 |

|

V0 |

Specimen: injection molded plaques in 2mm thickness.

Supply form and standard packaging

Noveon® ZHF78AT3 is supplied in pellet form and is packaged in polyethylene bags. Net weight 25kg.

*Please be aware that listed values are “typical (average) values” and should / can not be applied for specification purposes.

Material Preparation

Prior to processing, Noveon® ZHF78AT3 must be dried at 100oC during 4 hours.

It is recommended to dry the material in a dehumidifying type dryer. Target dew point to be preferably -40 oC. Depending on the applied processing technique, following maximum moisture levels are recommended.

Cable and tubing extrusion 0.05%

Processing Conditions

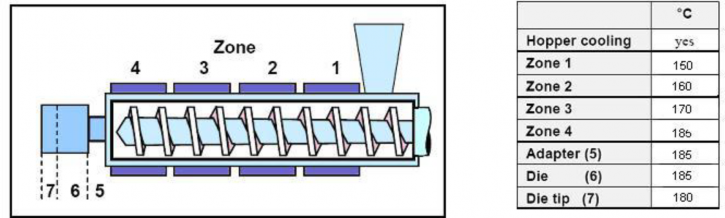

Noveon® ZHF78AT3 is extruded on any conventional extruder equipped with a PVC, 3 stage or barrier type screw having an L/D ratio of 25:1 and a compression ratio of 3:1.

Recommended extrusion temperature profile: